DR. BINGBING LI LABORATORY

ABOUT DR. BINGBING LI

Dr. Bingbing Li, Affiliate Faculty at the Terasaki Institute, is a Professor of Manufacturing Systems Engineering at California State University Northridge (CSUN) since 2014, and received his Ph.D. in Industrial Engineering from Texas Tech University in 2012. Dr. Li serves as the Assistant Director of DOE funded Industrial Training and Assessment Center (ITAC) at UC Irvine and CSUN (SMART ITAC), Director of Laboratory for Smart and Additive Manufacturing (LSAM). Dr. Li has published over 100 peer-reviewed journal and conference papers and secured external grants successfully, which brings his CSUN career total to $2.4 million as PI and $6.6 million as Co-PI. Dr. Li conducts research in Smart Manufacturing, Additive Manufacturing and Sustainable Manufacturing, mainly funded by NASA, DOD, DOE, NSF, CEC and industrial partners. He teaches undergraduate and graduate courses in the Manufacturing Systems Engineering program. Dr. Li is one of the Faculty Mentors of the NASA funded Autonomy Research Center for STEAHM (ARCS), NIH funded Building Infrastructure Leading to Diversity (BUILD) Promoting Opportunities for Diversity in Education and Research (PODER), and USDE funded HSI-STEM/ AIMS2 (Attract, Inspire, Mentor and Support Students). He is the Faculty Advisor of the Society of Manufacturing Engineers (SME) Student Chapter S327. Dr. Li is the member of the Society of Manufacturing Engineers (SME), American Society of Mechanical Engineers (ASME), and Association for Computing Machinery (ACM).

RESEARCH OVERVIEW

Dr. Bingbing Li’s Lab focuses on

1) Additive manufacturing (metal additive manufacturing, 3D bioprinting, design for additive manufacturing)additive Manufacturing (3D bioprinting, Metal AM, DfAM)

2) AI-powered design and manufacturing (Smart Connected Worker, Digital Twins, XR and Metaverse for Digital Manufacturing, Knowledge Graph-based AI Agent, Autonomous Growth System)smart Manufacturing (Smart Connected Worker, Digital Twins, AR/VR for Manufacturing), and

3) Sustainable Manufacturing (Energy Efficiency, LCA, Sustainability).Sustainable design and manufacturing (Green Design, Energy Efficiency, Life Cycle Assessment, Sustainability Analysis, Decarbonization, Disassembly, Recycling, Remanufacturing)

3D bioprinted MIA PaCa-2 human pancreatic cancer model

Fig. A & B: Schematic of 3D bioprinting of pancreatic organotypic microtumors employing GelMA/Laponite composite hydrogels. Fig. C & D: Representative images of Live/Dead Assay; Quantitative analysis of cell viability using PrestoBlue assay

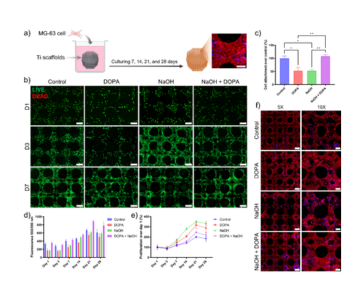

Explore the in-vitro and in-vivo study of bone implant through metal 3D printing

The preliminary results of our study show that the Ti scaffolds coated with DOPA, NaOH, or a combination of NaOH and DOPA, provide an environment that supports higher cell viability and growth compared to the uncoated Ti scaffolds. This was demonstrated by the higher proliferation ratios observed from day 1 to day 29.

Nanoparticles Enabled Laser Powder Bed Fusion of High Strength Aluminum Alloys

Scanning electron microscopy (SEM) and Energy-dispersive X-ray spectroscopy (EDS) results of as-printed Al alloy

Superalloy of tungsten and SS316L

Mechanical properties of as-printed SS316L

Strong yet ductile of oxide dispersion strengthened (ODS) SS316L via L-PBF

Successfully fabrication of SS316L with 0.5 and 1 wt.% Y2O3 nanoparticles

Exploration of dental implant through metal 3D printing

Design and optimization of dental implant

Consortium for High-volume Additive Manufacturing of Aerospace Heat Exchanger and Talent Development

Research objects: (1) develop robust super alloys by nanoparticles self-dispersion to improve the performance of heat exchanger; (2) identify best practices of the generative design for additive manufacturing (AM); (3) laser power bed fusion (LPBF) AM manufacturing; (4) NDE inspection of AM production parts for aerospace applications; (5) AI-powered Augmented Reality (AR) training for metal AM.